Contributions of HEC

Propeller Shaft for Navy

Hot Strip Mill

Contributions of HEC

10 T Hammer Head Tower Crane of HEC make installed at the top

Horizontal Sliding Door for Rocket Assembly

Contributions of HEC

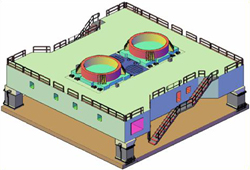

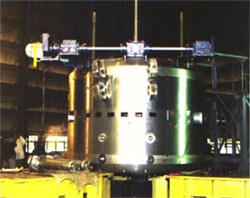

Super Conducting Cyclotron Magnet