| 30T Electric arc Furnace | 2 Nos. |

| 10T Electric arc Furnace | 1 No. |

| 5T Induction Furnace | 1 No. |

| 2T Induction Furnace | 1 No. |

VD UNIT

| 60T Vacuum Arc Degassing unit | 1 No |

| 90T Vacuum Degassing unit | 2 Nos. |

| 60T Ladle Furnace | 1 No |

VAD Furnace

| 6000T Hydraulic Press | 1 no. |

| 2650T Hydraulic Press | 1 no. |

| 1650T Hydraulic Press | 1 no. |

| 1000T Hydraulic Press | 1 no. |

| 3T/1.6T Hammer | 2 nos. |

| Die Forging Units | (15T & 1600 Kg) 1 each |

6000 T Press

| Low Frequency Induction Hardening M/c (50 Cycles) | 1 |

| Medium Frequency Induction M/c (1000 Cycles) | 1 |

| Nitriding Furnace | 1 |

| Thermal Stability Testing Equipment | 1 |

| Vertical & Horizontal Mist Quenching M/c (Up to 50T & 18M long jobs) |

2 |

| Electric H/T Pit Furnace up to 18 M Depth | 1 |

| Bogies Type H/T Furnace up to 12M x 6m x 3.5m | 2 |

| Bogies Type H/T Furnace up to 19M x 4m x 3m | 2 |

| Electric Pit Furnace dia 2.5M | 1 |

| Electric Pit Furnace dia 4.0 M | 1 |

| Name of Equipment | Model No. |

|---|---|

| Balzers Exalograph for Hydrogen, Nitrogen, Oxygen | 1960 |

| Spectrolab M-5 | M-5 1988 |

| Quantron | Magellan 2004 |

| Atomic Absorption Spectrophotometer - 902 | 902-1984 |

| Metallurgical Microscope | Neophot-1936 |

| Image Analyzer | 2002 |

| High Volume Air Sampler | APM-415 |

| Stack Gas Analyzer | APM-610 |

| Universal Testing M/C | ZD-40, ZD-10 |

| Brinell Hardness Testing M/C | HPO - 3000 |

| Vickers Hardness Testing M/C | HPO-250 |

| Rockwell Hardness Testing M/C | HP-25 |

| Notch Cutting M/C | 1044 |

| Charpy Testing M/C | PS-30 |

| IZOD Testing M/C | PS-30 |

| CNC Heavy Duty Gear Shaper | Pitch Dia Internal/External Gear 500 mm, Module Max 8mm |

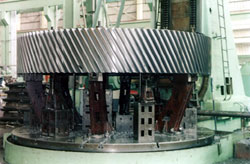

| Maag Gear Shaper (Speciality - Narrow Gap Herringbone gears) | Max. Dia 1800mm, Max. Module 18mm |

| Vertical Gear Hobbing M/C | Max Job Dia 5M, Module 50 mm, Max. Width of Job 2M |

| Horizontal Gear Hobbing M/C | Max Job Dia 5M, Module 40 mm, Max. Job Length 5.6M |

| Maag Gear Grinding Machines | Max. Dia 1800mm, Max. Module 0.5mm to 16mm |

| Lathes | Max. swing over bed 4M Max. distance between centres 20M |

| CNC Vertical Turning and Boring M/c (O&M Make) | Max Job Dia 14M Max Job weight 250T |

| CNC Planomilling M/c (Waldrich Coburg) | Max. Job size 3.5M x 7M x 2.5M Max Job weight 120T |

| CNC Hor. Boring M/c (Skoda Make) | Max. Spindle Dia 200mm Max Column Travel 20M |

| Gear Cutting M/c | Max. Job dia 5M Max. module 40mm (Hobbing |

Machining of HYDRO TURBINE SHAFT

Machining of Bull Gear for Steel Plant

| CNC Slant Bed Turning Centre | Distance Between Centres - 1500mm Swing Over carriage - 250mm |

| CNC Horizontal Machining Centre | Table size 1000 x 1000mm Travel 1800/1300/1000mm |

| CNC Vertical Machining Centre | Table Size 500 x 500mm Travel - x axis 1200mm, Y axis-510mm & z axis - 510mm |

| CNC Horizontal Boring Machine | Spindle Dia 200mm Table size 3500 x 4000mm |

| CNC Heavy duty Gear Shaper (Liebherr Make) | Pitch Dia - Internal Gear 500mm External Gear 500mm Module Max 8 m |

CNC Flame Cutting Machine