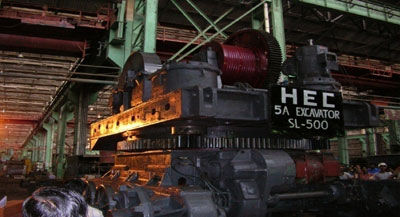

500th Excavator ready for dispatch (2008)

HEC successfully manufactured Magnet Poles and associated components for VECC (Department of Atomic Energy) and supplied in the year 2002.

Pole Tip Assembly

Cyclotron Magnet Assembly

15 nos. of machines were manufactured with Automatic Wheel Handling System to cater the production of 1 lakh wheels per year from rough forging to finish stage. These wheels are being supplied to INDIAN RAILWAYS for direct mounting on axles. The machines were equipped with FANUC 12 T with Auto Tool Changer.

The machine was designed & developed with Sinumerik 810 M.GA3. The machine was commissioned in 1994 at Field GUN Factory, Kanpur for deep hole drilling/trepanning of large size gun barrels. It's performance was appreciated by the user.

Designed for machining Concave / Convex profile on the copper mould to be used on continuous casting machine. The machine was developed with FANUC 0-MC CNC System for Rourkela Steel Plant, in the year 1995.

4 nos. of machines were developed & manufactured for rough & finish machining of Rolls with very high skin hardness. These machines with a use of FANUC 0-TD CNC System were supplied & commissioned at Bokaro steel Plant in the year 1997.